Wire forming processes suitable for customer needs, especially in the white goods and automotive sectors, are meticulously carried out. In the wire forming process, which starts with raw material supply, cutting, bending and welding processes are applied to wires of various diameters to ensure that the product reaches the desired final form.

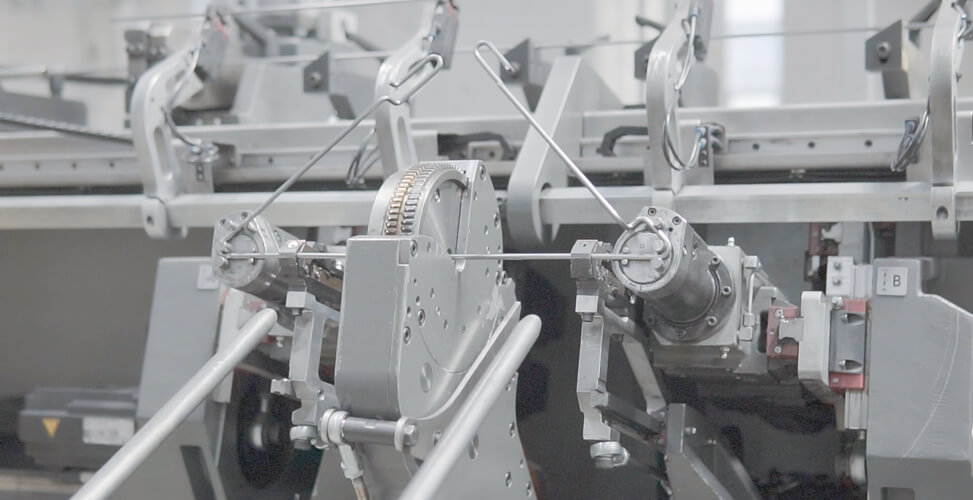

In the cutting process, the necessary cutting parameters are programmed to the wire cutting machines via the automatic control system interface. This programming ensures that the wire is cut in certain lengths with the precision appropriate to the product design. After cutting, the bending process is activated in order for the wire to take the desired geometric form. The bending process is carefully performed to meet both the functional and aesthetic requirements of the product.

In the welding stage, welding current is applied using spot welding and CNC welding machines. In this process, it is aimed to increase the durability and stability of the wire or assembled parts. After the welding process is completed, the strength, appearance quality and other properties of the welded joints are tested in detail in the mechanical laboratory.

In addition, quality control procedures are strictly applied throughout the wire forming process to ensure that the product complies with customer demands and industry standards. In this way, long life, durability and superior performance of the products produced are guaranteed.